Plastic waste grinder blades are specialized cutting tools used in machines designed to shred or grind plastic waste materials into smaller, more manageable pieces. These blades play a crucial role in the plastic recycling process by breaking down large plastic items—like bottles, containers, sheets, or other plastic scraps—into smaller flakes or granules that can be further processed or melted for reuse.

Key Features of plastic waste grinder blades:

- High Durability : Made from hardened steel or alloy materials to resist wear and tear during heavy-duty grinding.

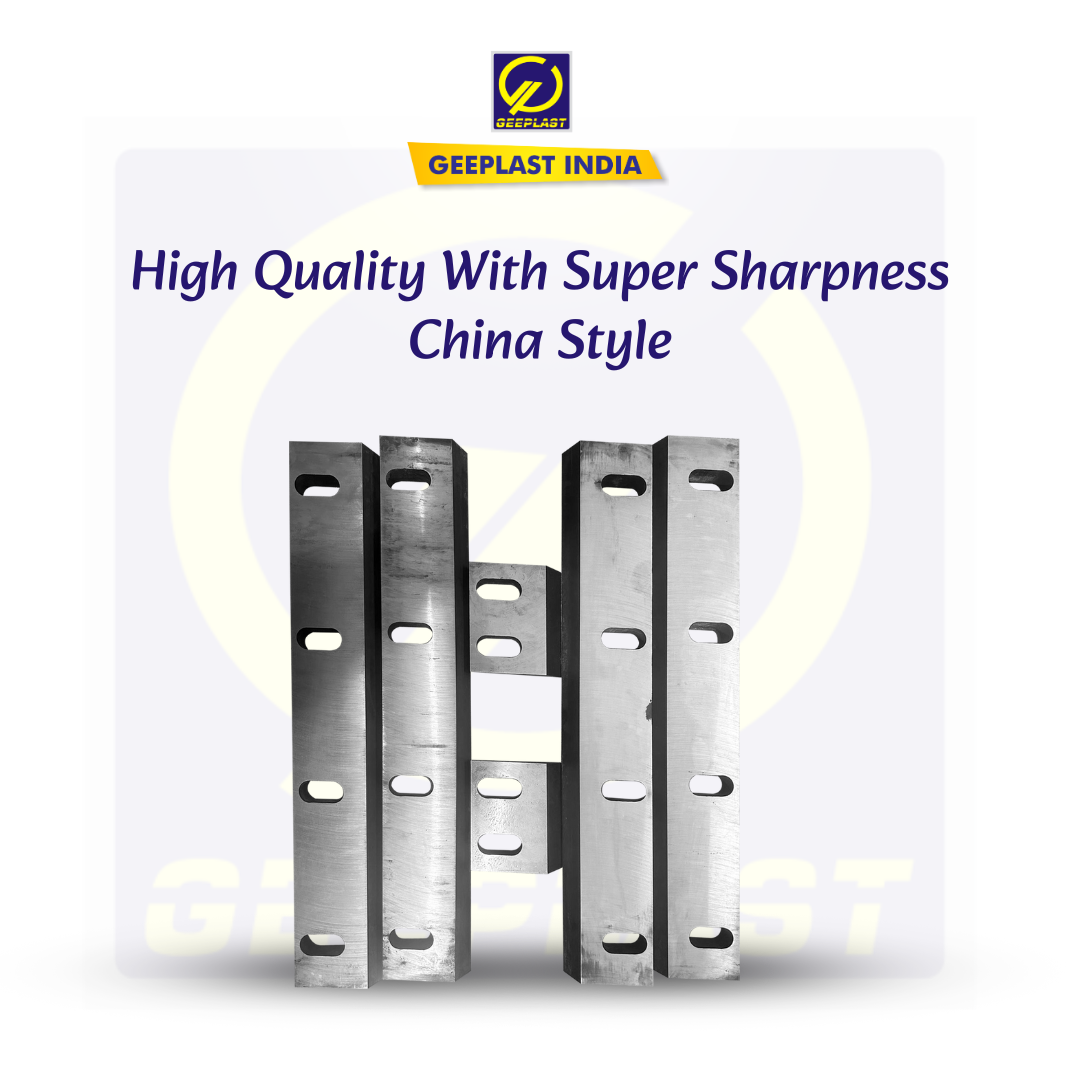

- Sharp Cutting Edges : Precisely sharpened blades ensure efficient and clean cutting of various plastic materials.

- Corrosion Resistance : Often treated or coated to prevent rust and corrosion, extending blade life in harsh environments.

- Customizable Sizes and Shapes : Blades can be designed to fit different grinder models and to handle specific types of plastic waste.

- Heat Resistance : Able to withstand the heat generated during high-speed grinding without losing hardness or shape.

- Balanced Design : Properly balanced to reduce vibration and noise during operation, ensuring smooth functioning of the grinder.

- Easy Maintenance and Replacement : Designed for quick sharpening, easy cleaning, and simple replacement when worn out.